Hazmat operations involve managing hazardous materials incidents, ensuring responder and public safety․ Proper training, equipment, and protocols are essential to mitigate risks effectively․

1․1 Definition and Importance of Hazmat Operations

Hazmat operations refer to the procedures and practices used to manage hazardous materials incidents safely․ These operations are critical for protecting people, the environment, and property from potential harm․ Hazmat incidents can arise from accidents, spills, or intentional releases, requiring specialized training and equipment․ The importance lies in preventing secondary risks, such as explosions or toxic exposure, while ensuring compliance with legal and safety standards․ Effective hazmat operations rely on coordinated efforts between first responders, emergency services, and regulatory agencies to mitigate threats efficiently․ Proper training and preparedness are essential to safeguard lives and minimize environmental damage during such events․

1․2 Brief Overview of Hazmat Classification

Hazmat classification organizes hazardous materials into distinct categories based on their risks; The primary system uses nine hazard classes, such as explosives, gases, flammable liquids, and oxidizers․ Each class has specific symbols and labels for quick identification․ Additional subclasses exist for materials with multiple hazards․ Classification ensures consistent handling, transportation, and emergency response․ Proper identification using labels, placards, and Safety Data Sheets (SDS) is crucial for responders to apply appropriate mitigation strategies․ Understanding these classifications is vital for safe and effective hazmat operations, enabling responders to assess risks and take necessary precautions․

Legal Framework and Regulations

Hazmat operations are governed by federal, state, and international regulations, including NFPA 472, OSHA standards, and DOT rules, ensuring compliance and safety in handling hazardous materials․

2․1 NFPA 472 Standard for Competence of Responders

The NFPA 472 Standard for Competence of Responders outlines the minimum requirements for hazardous materials response․ It establishes levels of training, from awareness to specialized operations, ensuring responders are prepared to handle incidents safely․ The standard emphasizes understanding hazard classification, risk assessment, and the use of personal protective equipment (PPE)․ Compliance with NFPA 472 ensures responders meet competency levels, reducing risks during Hazmat operations․ It also aligns with federal and state regulations, providing a consistent framework for training and response․ This standard is critical for ensuring the safety of both responders and the public during hazardous materials incidents․

2․2 Federal and State Hazmat Regulations

Federal and state regulations play a critical role in governing hazardous materials operations․ The Department of Transportation (DOT) and Environmental Protection Agency (EPA) enforce strict guidelines for handling, transporting, and storing hazardous materials․ These regulations ensure compliance with safety standards and minimize environmental risks․ State-specific laws often complement federal rules, adding localized requirements for hazmat response and disposal․ Understanding these regulations is essential for responders and organizations to avoid penalties and ensure public safety․ Proper documentation, training, and adherence to these laws are vital for effective hazmat management and incident response at both federal and state levels․

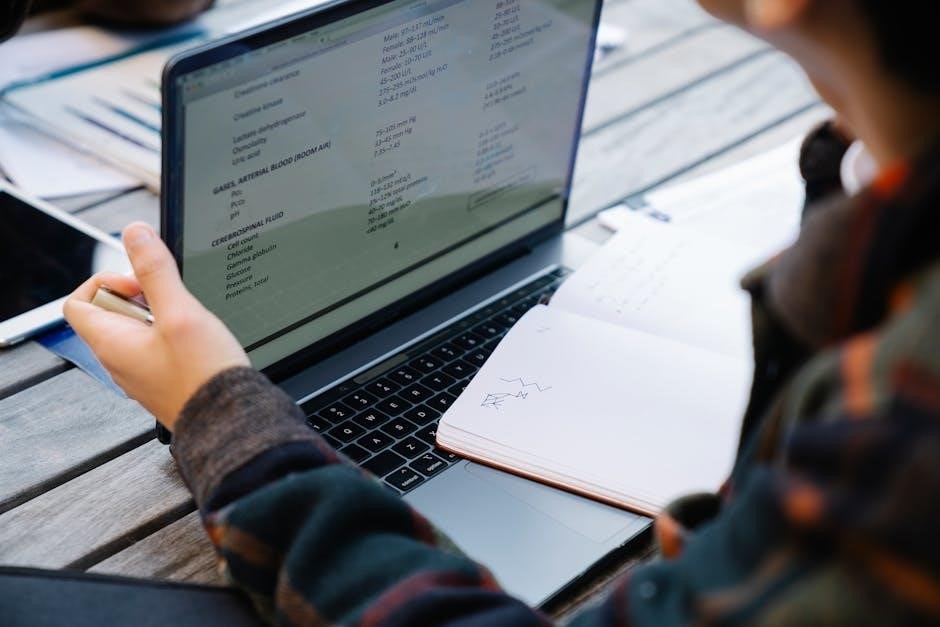

2․3 OSHA Standards for Hazmat Response

OSHA standards provide critical guidelines for hazmat response, ensuring worker safety and compliance․ The Hazardous Waste Operations and Emergency Response (HAZWOPER) standard (29 CFR 1910․120) outlines requirements for training, personal protective equipment (PPE), and site control measures․ Responders must undergo initial and annual refresher training to maintain certification․ OSHA also mandates hazard assessment, medical surveillance, and decontamination procedures․ These standards aim to minimize risks during hazmat incidents, ensuring responders are adequately prepared and protected․ Adherence to OSHA regulations is essential for maintaining a safe working environment and preventing occupational injuries or illnesses in hazmat operations․

Hazmat Identification and Classification

Hazmat identification involves recognizing materials through labels, placards, and class numbers․ Classification categorizes substances into nine hazard classes, guiding responders on risks and mitigation strategies effectively․

3․1 Understanding the Nine Hazard Classes

Understanding the nine hazard classes is critical for identifying and managing hazardous materials․ These classes include explosives, gases, flammable liquids, flammable solids, oxidizers, toxics, corrosives, and miscellaneous materials․ Each class represents unique risks and requires specific handling procedures․ For example, explosives pose detonation risks, while toxics threaten human health through exposure․ Proper identification using labels, placards, and safety data sheets is essential for safe response․ Responders must recognize these classifications to apply appropriate mitigation strategies and protect people and the environment from potential hazards․ This knowledge forms the foundation of effective hazmat operations and incident management․

3․2 Role of Material Safety Data Sheets (MSDS)

Material Safety Data Sheets (MSDS) are crucial documents in hazmat operations, providing detailed information on chemical products․ They outline hazards, safe handling procedures, and emergency response measures․ MSDS include data on physical properties, health risks, and environmental impacts․ First responders rely on MSDS to assess risks and implement safety protocols during incidents․ Employers use them to train workers on handling hazardous materials safely․ Compliance with MSDS guidelines ensures regulatory adherence and minimizes exposure risks, making them indispensable for both routine operations and emergency responses․ Their accuracy and accessibility are vital for protecting people and the environment from chemical hazards․ Proper use of MSDS is essential for safety․

Operational Planning and Preparedness

Operational planning ensures coordinated responses to hazmat incidents through structured plans, effective resource allocation, and regular drills, enhancing preparedness and adaptability through continuous improvement․

4․1 Developing Emergency Response Plans

Creating effective emergency response plans requires collaboration among stakeholders to identify potential hazards and outline clear procedures for containment, evacuation, and communication․ These plans must be tailored to specific scenarios, such as chemical spills or tanker leaks, ensuring all roles and responsibilities are clearly defined․ Regular reviews and updates are crucial to maintain relevance and compliance with regulations․ Training exercises and simulations help teams familiarize themselves with the plan, improving response efficiency during actual incidents․ A well-structured plan minimizes risks, protects personnel, and reduces environmental impact․

4․2 Conducting Risk Assessments

Risk assessments are critical in Hazmat operations to identify potential hazards and evaluate their severity․ They involve analyzing the type of material, quantity, and environmental conditions․ Responders must consider factors like wind direction, population density, and infrastructure to predict incident outcomes․ A thorough assessment helps prioritize actions, allocate resources, and implement safety measures․ It also ensures the protection of responders and the public by identifying safe zones and escape routes․ Regular reviews and updates to risk assessments are essential as incident dynamics can change rapidly․ Collaboration with experts and stakeholders enhances the accuracy of these evaluations, ensuring effective mitigation strategies․ Documentation of findings aids in post-incident analysis and future preparedness․

Training and Certification

Training and certification are essential for responders, ensuring compliance with NFPA 472 and OSHA standards․ Annual refreshers maintain proficiency in handling hazardous materials incidents safely․

5․1 Levels of First Responder Training

Hazmat first responder training is categorized into four levels: Awareness, Operations, Technician, and Specialist․ Awareness-level responders identify hazards and secure the area․ Operations-level responders take defensive actions, such as containment․ Technician-level responders perform offensive operations, including mitigation․ Specialists provide advanced support and oversight․ Each level requires specific knowledge and skills, ensuring a coordinated response․ Training must comply with NFPA 472 and OSHA standards, emphasizing hazard recognition, risk assessment, and equipment use․ Understanding these levels ensures effective response to hazardous materials incidents, promoting safety and minimizing risks to people and the environment․

5․2 Importance of Annual Refresher Training

Annual refresher training is mandatory for maintaining hazmat response certifications, ensuring responders stay updated on regulations and best practices․ This training reinforces critical skills, such as hazard identification, equipment use, and incident command․ It also addresses new challenges and emerging threats, keeping responders prepared for diverse scenarios․ Practical exercises and scenario-based learning enhance retention and readiness․ Refreshers are essential for compliance with federal and state regulations, including OSHA standards․ Regular training ensures a consistent and effective response to hazardous materials incidents, safeguarding both responders and communities․ It underscores the commitment to ongoing professional development in this high-risk field․

Case Studies and Scenario-Based Learning

Case studies and scenario-based learning provide practical insights into real-world hazmat incidents, enhancing responders’ critical thinking and preparedness through hands-on training and realistic simulations․

6․1 Real-World Examples of Hazmat Incidents

Real-world examples of hazmat incidents, such as chemical suicides and fuel tanker leaks, highlight the importance of preparedness and effective response strategies․ These incidents often involve unique challenges, including toxic fumes, explosive risks, and environmental contamination․ Analyzing such cases provides valuable insights into hazard identification, risk assessment, and mitigation techniques․ For instance, chemical suicide scenarios require immediate isolation of the area and specialized neutralization methods․ Fuel tanker leaks demand rapid containment to prevent environmental damage and fire hazards․ These examples emphasize the need for coordinated efforts between responders, ensuring safety and minimizing consequences․ Lessons learned from these incidents are crucial for improving future responses․

6․2 Simulating Chemical Suicide and Fuel Tanker Leak Scenarios

Simulating chemical suicide and fuel tanker leak scenarios provides responders with hands-on experience in high-stakes environments․ These exercises evaluate decision-making, teamwork, and adherence to protocols․ For chemical suicide simulations, responders practice isolating hot zones, identifying hazardous materials, and using neutralization techniques․ Fuel tanker leak scenarios focus on containment strategies, fire prevention, and environmental protection․ Both simulations incorporate real-world challenges, such as limited resources or unpredictable weather conditions․ These training exercises ensure responders are prepared to act swiftly and safely, minimizing risks to themselves and the public․ Regular simulation-based training is essential for maintaining proficiency and adapting to new threats․