The 14 ft Bounce Pro Trampoline is a durable, family-friendly outdoor entertainment solution, designed with safety and fun in mind, perfect for backyard enjoyment and exercise.

Overview of Features and Benefits

The 14 ft Bounce Pro Trampoline offers a spacious jumping area, durable galvanized steel frame, and UV-resistant mat for long-lasting use. It includes a sturdy enclosure for added safety, ensuring jumpers stay within the trampoline. The trampoline supports up to 220 lbs, making it suitable for both kids and adults. Additional features like the Electron Shooter Game enhance fun, while the classic enclosure provides stability and protection. Its design promotes safe, enjoyable, and active outdoor entertainment for the whole family.

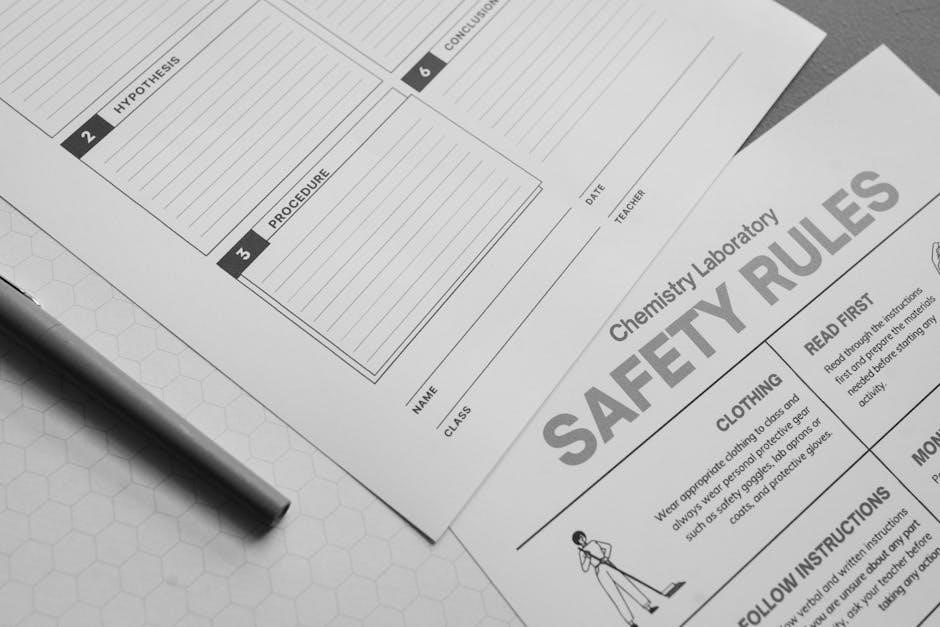

Safety Precautions and Guidelines

Always follow safety rules to ensure a secure experience. Avoid somersaults or flips, as they can cause serious injury. Only one person should use the trampoline at a time. Adult supervision is strongly recommended for children. Inspect the trampoline before each use to ensure all parts are secure and in good condition. Never allow jumpers to exit the trampoline by bouncing off.

General Safety Tips for Users

Ensure one person uses the trampoline at a time to minimize collision risks. Adults should supervise children during use. Avoid somersaults or flips, as they can lead to serious injury. Remove all sharp objects and loose jewelry before jumping. Enter and exit the trampoline carefully, avoiding bouncing off. Regularly inspect the mat, springs, and enclosure for damage. Never use the trampoline if damaged or after consuming alcohol/drugs. Follow weight limits and age restrictions for safe enjoyment.

Weight Capacity and Usage Restrictions

The 14 ft Bounce Pro Trampoline has a weight capacity of 220 lbs, ensuring safe use for multiple ages. Only one jumper is allowed at a time to prevent collisions. Somersaults and flips are strictly prohibited due to injury risks. Adult supervision is mandatory for children. The trampoline is designed for users aged 6 and above. Always adhere to these guidelines to ensure a safe and enjoyable experience. Consult the manual for detailed usage restrictions and recommendations.

Assembly Instructions

Assemble the 14 ft Bounce Pro Trampoline by attaching the frame, springs, and mat, then securing the enclosure. Follow the manual step-by-step for a safe setup.

Step-by-Step Assembly Process

Begin by unpacking and organizing all components. Attach the frame legs, then connect the upper and lower frame sections. Next, secure the springs to the mat and frame. Attach the safety enclosure, ensuring straps are tightly fastened. Follow the manual for specific instructions, such as wrapping elastic straps behind leg sockets. For models like TR-146STS-GN or TR-0123BGA-168, ensure proper alignment. Double-check all bolts and connections for stability.

Tools and Materials Required

Assembly requires a socket wrench, screwdrivers, and pliers. Ensure all hardware, including springs, bolts, and nuts, is included. The trampoline comes with a spring pull tool for attaching the mat. For models like TR-146STS-GN, you’ll need 72 heavy-duty springs and a weather-resistant mat. Refer to the manual for specific tools and materials, such as elastic straps for enclosure assembly. Organize all parts before starting to streamline the process.

Maintenance and Care

Regularly inspect the trampoline for wear and tear. Clean the mat with mild detergent and water. Lubricate moving parts to ensure smooth operation. Protect from harsh weather conditions and store during off-season to extend durability. Always check for loose springs or damaged pads and replace them promptly to maintain safety and performance.

Cleaning and Inspection Tips

Regularly inspect the trampoline mat, springs, and frame for damage or wear. Clean the mat with mild soap and water, avoiding harsh chemicals. Remove dirt and debris from the enclosure net and poles. Lubricate spring connections to prevent rust. Check for loose bolts or screws and tighten them. Inspect padding for tears and replace if necessary. Store the trampoline securely during off-season to protect from weather damage and extend its lifespan.

Storage and Protection During Off-Season

Store the trampoline in a dry, protected area during winter or extended periods of disuse. Clean the mat and frame thoroughly before storage to prevent mold and rust. Use a weather cover to shield it from rain and debris. Disassemble and store components like springs and padding separately. Keep the trampoline away from direct sunlight to avoid UV damage. Regular off-season maintenance ensures the trampoline remains durable and safe for future use.

Troubleshooting Common Issues

Identify and address common issues like frame damage or loose springs by inspecting regularly. Tighten hardware and replace worn parts promptly to ensure safety and functionality.

Identifying and Fixing Frame or Spring Problems

Regularly inspect the frame and springs for damage or rust. Tighten any loose hardware immediately to prevent structural instability. If a spring is damaged, replace it with a compatible part to ensure safety. Lubricate moving parts to maintain smooth operation. Always refer to the manual for specific instructions on replacing worn-out components. Neglecting these issues can lead to safety hazards, so address them promptly to keep your trampoline stable and secure.

Replacing Worn-Out Parts

To ensure the longevity and safety of your 14 ft Bounce Pro Trampoline, replace any worn-out parts immediately. Inspect the springs, mat, and safety pads regularly. Use only authorized replacement parts to maintain warranty and safety standards. When replacing springs, ensure they are securely attached to both the frame and mat. Lubricate moving parts to prevent rust and friction. Always follow the manual for detailed replacement instructions to avoid compromising the trampoline’s stability and performance.

Enclosure Setup and Safety

Ensure the enclosure is securely attached to the trampoline frame to prevent accidents. Regularly inspect the net and springs for wear and tear to maintain safety standards.

How to Secure the Enclosure Properly

To ensure the enclosure is properly secured, wrap elastic straps behind the leg sockets and tie tight knots. Use one-sided bows in front for added stability. Regularly check the enclosure’s attachments to ensure they are tightly fastened. Make sure all springs and straps are securely connected to prevent the net from shifting during use. Properly securing the enclosure helps prevent accidents and ensures a safe jumping experience for everyone.

Ensuring Enclosure Stability

For maximum stability, ensure the enclosure is tightly secured to the trampoline frame using durable straps and connections. Regularly inspect the straps and springs for wear and tear. Tighten any loose fittings to prevent the enclosure from shifting during use. Always follow the manufacturer’s assembly instructions to ensure proper alignment and balance. A stable enclosure provides a safer environment for jumpers and helps maintain the structural integrity of the trampoline system.

Accessories and Optional Features

The 14 ft Bounce Pro Trampoline offers exciting accessories like the Electron Shooter Game for interactive fun and additional safety pads for enhanced protection during use.

Electron Shooter Game Setup

The Electron Shooter Game adds interactive fun to your trampoline experience. Designed for the 14 ft Bounce Pro Trampoline, it includes targets and accessories for competitive play. Follow the manual to attach the game components securely to the enclosure. Ensure all connections are tight to prevent loose parts. This feature is perfect for kids, promoting active play and family bonding while maintaining safety with proper setup and supervision.

Adding Safety Pads and Other Accessories

Enhance your trampoline experience by adding safety pads and accessories. The 14 ft Bounce Pro Trampoline supports additional safety pads for extra cushioning around the springs and frame. Accessories like replacement springs, mats, and enclosures can maintain performance. Optional features such as the Electron Shooter Game add fun for kids. Always ensure accessories are compatible and installed correctly to uphold safety and durability, following the manual’s guidance for secure and proper fitting.

Jumping Techniques and Fun Ideas

Master basic jumping techniques for beginners, then progress to advanced tricks like flips and somersaults. Add fun with games like trampoline Dodgeball or obstacle courses for endless family enjoyment.

Basic Jumping Techniques for Beginners

Start with small, controlled jumps to build confidence and balance. Bend your knees upon landing to absorb impact gently. Keep your arms out for stability and focus on staying centered. Avoid overcomplicating movements initially. As you gain comfort, gradually increase jump height and experiment with basic footwork, like shuffling or hopping sideways. Always maintain a safe distance from others and the enclosure to ensure a fun, injury-free experience for everyone.

Advanced Tricks and Safety Considerations

For experienced users, advanced tricks like flips and somersaults can enhance fun, but always prioritize safety. Ensure proper technique and supervision, especially for children. Avoid risky moves without adequate training or padding. Never exceed the weight capacity or attempt tricks beyond your skill level. Regularly inspect equipment for wear and tear to prevent accidents. Follow manufacturer guidelines and practice in a supervised environment to enjoy a safe and thrilling experience.

The 14 ft Bounce Pro Trampoline offers endless fun and exercise for families. Always follow safety guidelines, inspect equipment regularly, and maintain proper upkeep for lasting enjoyment and safety.

Long-Term Maintenance for Durability

Regularly inspect the 14 ft Bounce Pro Trampoline frame, springs, and mat for wear or damage. Clean the surface with mild soap and water to prevent dirt buildup. Tighten all bolts and connections periodically to ensure stability. Protect the trampoline from harsh weather by storing it during off-season or using a cover. Replace worn-out parts promptly to maintain safety and performance. Proper care extends the lifespan and ensures years of safe, enjoyable use.

Enjoying Your Trampoline Responsibly

Always supervise children and ensure only one user is on the trampoline at a time. Avoid somersaults or flips, as they can cause serious injury. Check the weight capacity and adhere to it strictly to prevent damage. Regularly inspect for wear and tear before use. Follow all safety guidelines and instructions provided. By being responsible, you can create lasting memories and ensure a safe, enjoyable experience for everyone.