Lionel service manuals provide essential guidance for maintaining and repairing Lionel model trains, offering detailed instructions, diagrams, and parts lists. Available as PDF downloads, these manuals ensure enthusiasts can troubleshoot and restore their locomotives, rolling stock, and accessories with precision. Whether for vintage or modern trains, Lionel service manuals are indispensable resources for hobbyists and collectors, available through official sources and third-party websites.

Overview of Lionel Service Manuals

Lionel service manuals are comprehensive guides designed to help users maintain, repair, and operate Lionel model trains and accessories. These manuals cover a wide range of products, including diesel engines, steam locomotives, and rolling stock. They provide detailed instructions, exploded diagrams, and parts lists, ensuring enthusiasts can troubleshoot and restore their trains effectively. Available in PDF format, Lionel service manuals are accessible online, with options to download from official Lionel websites or third-party sources. Key manuals include the Lionel 249 and 249E, ZW Transformer, and 2023 Union Pacific Diesel service manuals. These resources are invaluable for hobbyists, offering clear, step-by-step guidance to keep Lionel trains running smoothly. They cater to both vintage and modern models, ensuring longevity and performance.

Importance of Using Official Lionel Service Manuals

Using official Lionel service manuals ensures accuracy and reliability when maintaining or repairing Lionel model trains. These manuals are crafted by Lionel experts, providing precise instructions and genuine parts information. They help prevent costly mistakes and potential damage from incorrect repairs. Official manuals also include safety guidelines and warranty information, protecting both the user and the product. Compared to third-party manuals, official versions are updated regularly, incorporating the latest technical advancements. They are essential for preserving the longevity and functionality of Lionel trains, whether vintage or modern. By adhering to official manuals, enthusiasts can maintain their trains’ authenticity and performance, ensuring a seamless and enjoyable hobby experience.

Where to Find Lionel Service Manuals Online

Lionel service manuals can be conveniently found online through various reliable sources. The official Lionel website offers a dedicated section for product manuals, ensuring authenticity and ease of access. Additionally, third-party websites like ManualsLib and eBay provide a wide range of Lionel service manuals in PDF format. Hobbyist forums and collector communities often share these manuals, fostering a supportive environment for enthusiasts. Some platforms may charge a small fee, while others offer free downloads. Ensuring the manual is verified as authentic is crucial to avoid misinformation. By exploring these options, users can easily locate and download the specific Lionel service manual they need for their model trains or accessories.

History of Lionel Service Manuals

Lionel service manuals have been essential resources for model train enthusiasts since the early 20th century, evolving from printed guides to digital PDF formats for easy access.

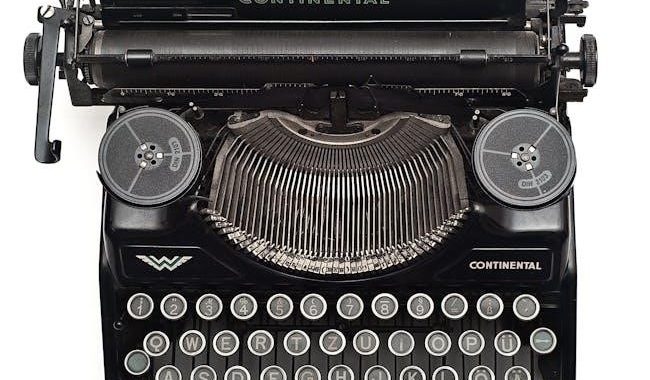

Evolution of Lionel Service Manuals Over the Years

Lionel service manuals have undergone significant transformations since their inception. Initially, they were printed as comprehensive guides, often accompanied by detailed diagrams and parts lists. With the advent of digital technology, these manuals transitioned into PDF formats, enhancing accessibility and convenience. Today, enthusiasts can download Lionel service manuals for various models, including diesel engines, steam locomotives, and rolling stock. This shift to digital has not only preserved the wealth of information but also made it easier for hobbyists to maintain and repair their trains. The evolution reflects Lionel’s commitment to supporting collectors and ensuring their products remain functional and enjoyable for generations.

Key Milestones in Lionel Service Manual Development

Lionel service manuals have marked significant milestones, reflecting advancements in both content and accessibility. Early editions were detailed, offering schematics and repair guidance for iconic models like the Lionel 249 and 249E locomotive. The 1930s saw comprehensive manuals with exploded views, setting a standard for clarity. Post-war, manuals expanded to cover new train designs, including the Lionel ZW Transformer. The 2023 Union Pacific Diesel manual introduced color photography and updated repair procedures. Digital versions emerged, offering PDF downloads for easy access. These milestones highlight Lionel’s dedication to providing precise, user-friendly resources, ensuring enthusiasts can maintain and restore their trains effectively. Each development has enhanced the utility of these manuals, catering to both vintage and modern collectors.

How Lionel Service Manuals Have Adapted to Modern Technology

Lionel service manuals have embraced modern technology to enhance accessibility and user experience. Traditionally printed, these manuals are now widely available as downloadable PDFs, offering instant access to enthusiasts worldwide. They often feature interactive elements, such as hyperlinked indexes and searchable content, making navigation easier. High-resolution images and color diagrams provide clarity for complex repairs. Additionally, Lionel has introduced web-based platforms where users can download specific sections or entire manuals, reducing storage needs. Compatibility with mobile devices allows hobbyists to reference manuals on the go. These advancements ensure that Lionel service manuals remain relevant and user-friendly in the digital age, catering to both vintage and modern train enthusiasts.

Types of Lionel Service Manuals

Lionel service manuals cover various train types, including diesel engines, steam locomotives, and rolling stock, along with accessories. Each manual provides specific repair and maintenance guidance.

Lionel Service Manuals for Diesel Engines

Lionel service manuals for diesel engines are comprehensive resources designed to help users maintain and repair their diesel locomotives. These manuals include detailed schematics, parts lists, and troubleshooting guides. They cover models like the Lionel No. 2023 Union Pacific Diesel, offering step-by-step instructions for various repairs. With these manuals, enthusiasts can address issues such as engine performance, electrical systems, and mechanical components. Available in PDF format, they are easily accessible and printable, ensuring that hobbyists can keep their diesel engines in prime condition. Whether for routine maintenance or complex overhauls, these manuals are invaluable for preserving the functionality and longevity of Lionel diesel locomotives.

Lionel Service Manuals for Steam Locomotives

Lionel service manuals for steam locomotives provide detailed guidance for maintaining, repairing, and restoring these classic models. Manuals like the Lionel 249 and 249E (1936-1939) offer comprehensive instructions for steam-era trains, covering mechanical components, electrical systems, and maintenance tips. They are essential for collectors and enthusiasts seeking to preserve the functionality and historical accuracy of their locomotives. Available in PDF format, these manuals are easily accessible and compatible with various devices, ensuring that users can reference them anytime. With step-by-step instructions and exploded views, they empower hobbyists to tackle repairs confidently, keeping their steam locomotives in optimal condition for years to come.

Lionel Service Manuals for Rolling Stock and Accessories

Lionel service manuals for rolling stock and accessories offer comprehensive guides for maintaining and repairing freight cars, passenger cars, and related components. These manuals provide detailed schematics, parts lists, and troubleshooting tips, ensuring enthusiasts can restore and maintain their accessories effectively. Available in PDF format, they cover a wide range of products, from vintage to modern designs. With clear instructions and visual aids, these manuals empower users to address common issues, such as wheel alignments and coupling mechanisms, and ensure optimal performance. They are indispensable resources for collectors and hobbyists aiming to preserve the functionality and longevity of their Lionel rolling stock and accessories.

Notable Lionel Service Manuals

Notable Lionel service manuals include the Lionel 249 and 249E, ZW Transformer, and 2023 Union Pacific Diesel manuals, providing detailed repair and maintenance guidance for enthusiasts.

Lionel 249 and 249E Service Manual (1936-1939)

The Lionel 249 and 249E Service Manual, covering models from 1936 to 1939, is a 10-page PDF download available for $10. It focuses on repair and replacement parts for these iconic locomotives. This manual is part of a larger 400-page publication and includes detailed instructions, diagrams, and exploded views. It’s a valuable resource for collectors and restorers, offering insights into maintaining and upgrading vintage Lionel trains. The manual is compatible with web browsers and works on both Mac and Windows. It’s often mentioned alongside Greenbergs’ Repair & Operating Manual, which serves as a complementary guide. This document is essential for enthusiasts aiming to preserve the legacy of these historic models.

Lionel ZW Transformer Service Manual

The Lionel ZW Transformer Service Manual is a comprehensive guide for operating and maintaining the ZW transformer, a crucial component for powering Lionel trains. Available as a PDF download, this manual covers features, functionality, and safety guidelines. It includes detailed instructions on installation, troubleshooting, and maintenance. With clear diagrams and step-by-step procedures, the manual ensures users can optimize their transformer’s performance. Safety precautions are emphasized to prevent electrical hazards. Compatible with web browsers, it’s accessible on both Mac and Windows systems. This resource is indispensable for hobbyists and collectors, providing everything needed to keep the ZW transformer in peak condition. Regular updates ensure it remains relevant for modern users.

Lionel 2023 Union Pacific Diesel Service Manual

The Lionel 2023 Union Pacific Diesel Service Manual is a detailed guide for the Lionel No. 2023 diesel-type locomotive, modeled after 1500 horsepower freight diesels. This PDF manual provides comprehensive instructions for maintenance, repair, and operation. It includes exploded views, parts lists, and troubleshooting tips, ensuring users can keep their model in optimal condition. Designed for both hobbyists and collectors, the manual offers clear diagrams and step-by-step procedures. Compatible with modern devices, it’s accessible via web browsers on Mac and Windows systems. The manual is a valuable resource for anyone seeking to restore or maintain their Lionel 2023 Union Pacific Diesel, ensuring it runs smoothly for years to come.

Downloading and Accessing Lionel Service Manuals

Lionel service manuals are available as PDF downloads from official Lionel websites and third-party sources, priced between $5 to $10, compatible with Mac and Windows systems.

Official Sources for Lionel Service Manuals

Official Lionel service manuals are available through Lionel’s website, ensuring authenticity and reliability. These PDF downloads are compatible with both Mac OS and Windows systems, offering clear instructions and diagrams.

The manuals are priced between $5 to $10, providing affordable access to essential repair and maintenance guides.

Additionally, Lionel Product Support offers a range of resources, including software upgrades, tips, and instructional videos, further enhancing the user experience.

By accessing these manuals directly from Lionel, users can trust the information to be accurate and up-to-date, ensuring their model trains are well-maintained and functioning optimally.

This official support underscores Lionel’s commitment to helping enthusiasts preserve and enjoy their collections.

Third-Party Websites Offering Lionel Service Manuals

Several third-party websites provide Lionel service manuals, offering convenient access to PDF downloads. Websites like Scribd and ManualsLib host a variety of Lionel manuals, including those for diesel engines and vintage models.

These platforms often allow free downloads, making them a popular choice for enthusiasts.

Additionally, some third-party sellers offer Lionel service manuals at affordable prices, typically ranging from $5 to $10 per manual.

While these sources can be helpful, users should verify the authenticity and completeness of the manuals to ensure they are reliable.

Third-party websites expand the availability of Lionel service manuals, catering to collectors and hobbyists seeking specific or hard-to-find guides.

How to Verify the Authenticity of Lionel Service Manuals

Verifying the authenticity of Lionel service manuals ensures users receive accurate and reliable information. Start by checking the publisher—official Lionel manuals are published by Lionel Trains, Inc.

Look for the Lionel logo and copyright information, typically found on the cover or within the document.

Cross-reference the manual’s content with Lionel’s official website or authorized dealers to confirm consistency.

Be wary of low-resolution scans or poorly formatted text, as these may indicate unofficial sources.

Additionally, check for specific part numbers, diagrams, and model details that match your train set.

Authentic manuals are usually priced moderately, so avoid excessively cheap options.

By following these steps, enthusiasts can ensure they are using genuine Lionel service manuals for their model trains.

Using Lionel Service Manuals Effectively

Lionel service manuals are vital tools for model train enthusiasts, providing detailed diagrams, part lists, and troubleshooting guides. By following the structured instructions, users can perform repairs efficiently, ensuring optimal performance and longevity of their trains. These manuals are essential for maintaining and upgrading Lionel locomotives and accessories, offering clear step-by-step guidance for both novice and experienced hobbyists.

Understanding the Structure of Lionel Service Manuals

Lionel service manuals are meticulously organized to ensure easy navigation and clarity. Each manual typically begins with an introduction, followed by detailed sections on parts lists, diagrams, and troubleshooting guides. The manuals are divided into logical categories, such as maintenance, repair, and operation, making it simple for users to locate specific information. Diagrams and exploded views are often included to visually guide users through complex procedures. Additionally, troubleshooting sections provide step-by-step solutions to common issues, helping enthusiasts resolve problems efficiently. The structured format ensures that both novice and experienced hobbyists can utilize the manuals effectively, enhancing their ability to maintain and restore Lionel trains with confidence and precision.

Essential Tools and Resources Mentioned in Lionel Service Manuals

Lionel service manuals outline the essential tools and resources needed for effective maintenance and repair. Commonly recommended tools include screwdrivers, pliers, wrenches, and voltage testers to ensure safe and accurate adjustments. Additionally, manuals often reference specialized tools specific to Lionel products, such as track cleaners and lubrication kits, to maintain optimal performance. Resources like exploded diagrams and parts lists are frequently included, providing visual guidance for disassembly and reassembly. Many manuals also point to instructional videos and online support materials, offering a comprehensive approach to troubleshooting and repair. These tools and resources empower users to handle tasks confidently, ensuring their Lionel trains operate smoothly and efficiently for years to come.

Tips for Troubleshooting Using Lionel Service Manuals

Lionel service manuals provide valuable troubleshooting tips to diagnose and resolve common issues with model trains. Start by systematically checking power connections and electrical components, as manuals often highlight these as primary sources of problems. Use diagnostic charts and symptom tables to identify specific faults, such as malfunctioning motors or faulty transformers. Always refer to wiring diagrams for clarity when dealing with electrical issues. Practical advice includes testing components with multimeters and ensuring proper lubrication of moving parts. Manuals also emphasize the importance of using genuine Lionel replacement parts for reliable repairs. By following these guidelines, users can efficiently troubleshoot and restore their trains to optimal performance, ensuring years of enjoyment and operation.

Safety Guidelines in Lionel Service Manuals

Lionel service manuals emphasize disconnecting power before repairs, using insulated tools, and avoiding live circuits. Always wear protective gear and follow proper repair procedures to ensure safety.

General Safety Precautions

When performing maintenance or repairs using Lionel service manuals, always prioritize safety. Disconnect power sources before starting work and use insulated tools to prevent electrical shocks. Wear protective gear, including gloves and safety glasses, to minimize risks. Ensure the workspace is well-lit and free from clutter to avoid accidents. Never attempt repairs near water or in damp conditions, as this increases the risk of electrical hazards. Keep loose clothing and long hair tied back to prevent entanglement with moving parts. Additionally, avoid working on Lionel products when fatigued or in a hurry, as this can lead to errors. Always follow the manufacturer’s guidelines and warning labels to ensure safe and effective repairs.

Specific Safety Warnings for Lionel Products

Lionel service manuals emphasize critical safety warnings tailored to their products. Electrical components, such as transformers like the Lionel ZW, can deliver lethal voltages, requiring extreme caution. High-current outputs can cause severe burns or fires if mishandled. When servicing locomotives, ensure all power is off and capacitors are discharged, as residual charges can still be dangerous. Moving parts, like wheels and gears, can pinch or crush if not properly secured. Additionally, Lionel manuals advise against modifying products beyond specified guidelines, as this can lead to unstable operation. Always verify the correct replacement parts to avoid compatibility issues that might pose safety risks. Adhering to these warnings ensures safe maintenance and continued enjoyment of Lionel trains.

Best Practices for Safe Maintenance and Repair

For safe Lionel train maintenance, always disconnect power before starting work. Use insulated tools to prevent electrical shock, especially with components like transformers. Refer to the specific service manual for your model to ensure correct procedures. Wear protective eyewear and gloves when handling small parts or tools. Keep work areas well-lit and clear of clutter to avoid accidents. Never bypass safety features or skip recommended steps. Test repairs with low voltage initially to check for issues. Properly discharge capacitors and avoid touching electrical contacts. Store loose parts securely to prevent loss or damage. Regularly inspect wires and connections for wear. By following these practices, you maintain safety and preserve the longevity of your Lionel trains.

Lionel service manuals remain invaluable for hobbyists and collectors, offering detailed guidance for maintenance and repair. Accessible as PDFs, they ensure safe and effective upkeep of Lionel trains.

Final Thoughts on the Importance of Lionel Service Manuals

Lionel service manuals are indispensable for enthusiasts and collectors, providing detailed guidance for maintenance, repair, and operation of Lionel trains. These comprehensive resources offer parts lists, troubleshooting tips, and safety guidelines, ensuring that users can keep their locomotives and accessories in prime condition. Available as downloadable PDFs, they cater to both vintage and modern models, making them accessible to a wide range of hobbyists. By following the instructions in these manuals, users can restore and operate their trains with confidence, preserving their functionality and heritage for years to come. Their value lies not only in practicality but also in their role in sustaining the legacy of Lionel trains.

How to Stay Updated with the Latest Lionel Service Manuals

To stay updated with the latest Lionel service manuals, enthusiasts should regularly visit the official Lionel website, which offers a dedicated section for downloadable PDFs. Subscribing to Lionel’s newsletter or following their social media channels can also provide notifications about new or updated manuals. Additionally, third-party forums and communities often share links to the latest releases. Users can also bookmark trusted third-party websites that specialize in hosting Lionel service manuals. By maintaining an active online presence and leveraging these resources, hobbyists can ensure they always have access to the most current information and support for their Lionel trains, keeping their collection in optimal condition. This proactive approach guarantees they never miss essential updates.